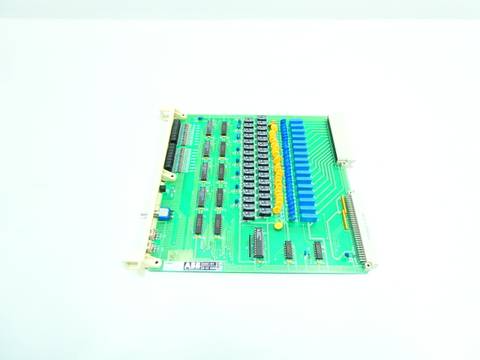

BENDER WR150X350S

Welcome to AE Automation Ultra

Delivering cutting-edge automation technologies.

Understanding the BENDER WR150X350S: Importance in Electrical Engineering

In the realm of industrial automation, the BENDER WR150X350S stands out as a pivotal component that enhances safety and efficiency in electrical systems. As industrial environments evolve with the integration of high-tech solutions, understanding devices like the BENDER WR150X350S becomes essential for electrical engineers and automation professionals alike.

Technical Specifications: Complying with IEC60947-2

The BENDER WR150X350S is designed in accordance with the IEC60947-2 standard, which outlines the requirements for low-voltage switchgear and control gear. This compliance ensures that the device meets rigorous safety and performance criteria, making it suitable for a wide range of applications.

- Rated Voltage: 150V AC to 350V AC

- Frequency: 50/60 Hz

- Operating Temperature: -20°C to +55°C

- Insulation Resistance: >100 MΩ

- Protection Class: IP54

These specifications highlight the WR150X350S’s robustness, making it ideal for use in environments where electrical reliability is critical. Its ability to withstand extreme conditions while maintaining performance is a testament to its engineering excellence.

Applications in Industrial Automation and Renewable Energy

The applications of the BENDER WR150X350S extend across various sectors, particularly in industrial automation and renewable energy. In industrial settings, this device is employed in monitoring and controlling electrical systems, ensuring that machinery operates within safe parameters. The integration of such devices enhances operational efficiency and minimizes downtime, which is crucial for maintaining productivity in automated processes.

In the renewable energy sector, the WR150X350S plays a significant role in managing power distribution and ensuring the safety of electrical installations. With the rise of solar and wind energy systems, this device helps in monitoring the performance of inverters and transformers, contributing to the overall reliability of renewable energy sources. Its ability to detect faults and anomalies is vital for preventing costly damage and ensuring continuous energy supply.

Conclusion

The BENDER WR150X350S serves as a prime example of how advanced electrical engineering solutions can enhance industrial automation and renewable energy applications. By adhering to stringent standards like IEC60947-2, it ensures safety, reliability, and efficiency in critical systems.

For more information on electrical engineering standards, you can visit the International Electrotechnical Commission (IEC).

To explore more about industrial automation technologies, check out our other resources at AE Automation Ultra.